TRUSTED BY

HACCP and Product Quality Services

Recording cooking and cooling profiles is critical in ensuring lethality (F0) and pasteurisation (PU) limits are reached for a quality product and HACCP compliance. Our HACCP services provide key metrics for reviewing product quality and improving the efficiency in production lines. We provide food safety management systems in the form of self-contained data loggers, which are an inexpensive and an accurate alternative to the more alternative methods of collecting temperature data using long wires or large metal insulation boxes.

Application Specific Food Sensor Technology

Select from a wide range of food temperature sensors, comprising of rapid response temperature probes suitable for insertion into small food products like prawns and more imposing ones for insertion into a leg of lamb.

Data Logger Shields, Fixtures & Fittings

We supply application specific accessories designed to protect the data loggers and keep them where you always need them to ensure an accurate food temperature monitoring system.

Food Safety Monitoring within Canning and Packaging

Use our fittings to fix the data logger to the outside of the products packaging and ensure the food temperature sensor technology is consistently in the correct position.

Thermal Shields

Profile ovens at elevated temperatures using our low cost thermal shields, designed to meet your cooking profile time vs temperature duration.

Magnets and brackets

Clips to hold the food temperature sensor in place and ensure the data logger remains in your desired location during the food safety validation process.

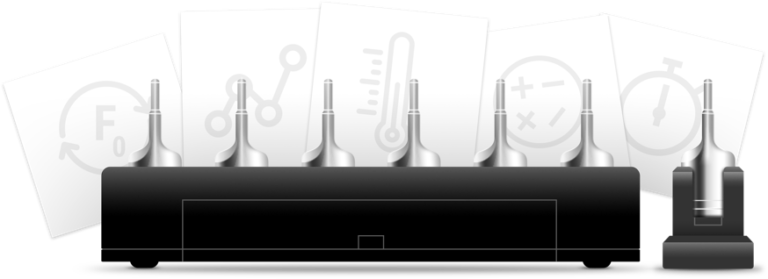

Multi point configuration and analysis

Rapidly configure multiple data logger food safety monitoring systems using the IFC406 interface and setup workflows. Automate the management of your data and presentation of reports incorporating multi plot graphs, table of time stamped temperature readings and configurable statistics including; min, max, F0, PU, time over/under temperature, and maths channels.

Food Safety Validation

Benefits at a glance

- Rapid batch configuration

- 0.1°C Accuracy

- Analytical and reporting software

- Robust stainless steel construction

- A probe tip for every application

More about

Thermal Validation

Thermal Validation Monitoring

Overview

Our thermal validation systems are comprised of the best data loggers in the industry, designed to deliver precise data within environments running at extreme temperatures and pressures.

Thermal Validation Monitoring

Real-Time Validation

Our closed door real time validation services enable data collection inside ovens, freezers and chambers to be viewed in real-time using robust data loggers with integral wireless radio modules.

Thermal Validation Monitoring

Autoclave

Achieve autoclave validation with durable wireless data loggers designed to withstand pressure and elevated temperatures whilst collecting accurate and repeatable data for extraction to a computer.

Want to find out more?

Please send us an email with details of your requirements or pick up the phone!